It is common for wood floorboards to suffer damage or cracks if they’ve been subjected to heavy blows or impact. Sometimes old age and low maintenance over the years can make this happen too. In these situations, you’ll need to replace the old wood boards with new wood boards. The only problem is that your new wood boards probably won’t match the existing wood boards that are still on the floor.

What do you do in this situation? You could try going to a home improvement store or lumber yard, but they’re probably not going to have a wood colour to match the old wood boards of your home. They may have modern colours for newer homes made within the last 20 or 30 years. But if your home’s wood flooring is over 50 years old, then it’ll be virtually impossible to find a new wood floor to match the colour.

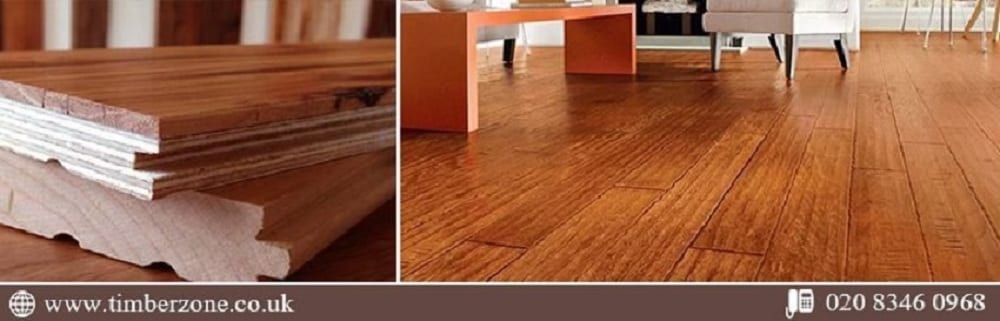

Therefore, your only solution is to blend the old wood flooring with the new wood flooring. Some people will rearrange their old and new floorboards in order to create a custom pattern or design on the floor. If you’re only replacing a couple of boards, then try staining your new floorboards with a colour which matches the old floorboard colour. You can find a plethora of coloured stain solutions at any hardwood store or home improvement store.

Before you stain the new wood boards, make sure you sand them down first. After the stain is applied, a sealer or finish coat goes over the stain. This will do the best job possible in imitating the original look of the flooring. Now just replace the wood boards with the new ones that you’ve stained and coated with sealer.

If there are still some colour differences between the wood boards on the floor, then consider staining all of them together with the same colour. You’ll need a professional floor sander, vacuum, stain roller, and other commercial quality equipment to perform this task. But if you take the time to stain everything the same colour, then you’ll have no inconsistences in the appearance whatsoever.

Staining the whole floor is only needed if you have several damaged wood boards to replace. If you only have a few boards, then you can just focus on staining the replacement boards instead.